Fire protection solutions for industry

We have been a partner to industry for many years and, with our HENSOTHERM® and HENSOMASTIK® product lines, we offer a wide range of options and solutions for passive fire protection, e.g. in aviation, shipping, railway vehicles, for power plant construction, in the field of renewable energies, the automotive sector and e-mobility, electrical and information technology and for door construction. Our fire protection systems are already used on numerous components made of different materials and substrates, such as various plastics, wood, sheet metal, aluminium, steel, stainless steel, electrical cables, pipes, insulation and also for sealing joints. Do you need a fire protection solution for your product? Call us on +49 40 72 10 62-48 – we’ll be pleased to advise you.

Fire protection in aviation

With the HENSOTHERM® | HENSOMASTIK® products, we offer solutions for fire protection requirements on lightweight and aircraft parts made of various plastics, wood and aluminium, and also for joint sealing.

Fire protection in shipping

With the HENSOTHERM® | HENSOMASTIK® products we offer solutions for fire protection requirements on components for vessels made of wood, electrical cables, pipes and for joint sealing.

Fire protection in railway vehicles

With theHENSOTHERM® | HENSOMASTIK® products, we offer solutions for fire protection requirements on components made of various plastics, wood, sheet metal, stainless steel, aluminium, electrical cables, pipes, for bonding insulation materials and for joint sealing. > Read more

Fire protection for renewable energies

With the HENSOTHERM® | HENSOMASTIK® products, we offer solutions for fire protection requirements on components made of various plastics, sheet metal, stainless steel, aluminium, on electrical cables and pipes. > Read more

Fire protection in power plants

With the HENSOTHERM® | HENSOMASTIK® products, we offer solutions for fire protection requirements for fire barriers, on electrical cables, on pipes, for joint sealing and for steel structures. > Read more

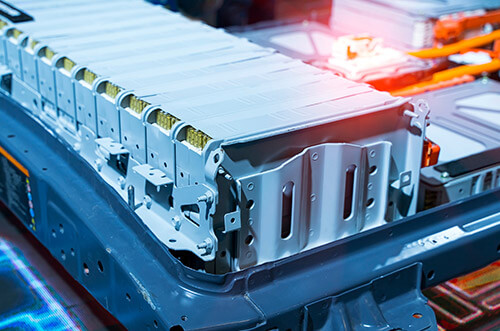

Fire protection in the automobile industry

With the HENSOTHERM® | HENSOMASTIK® products, we offer solutions for fire protection requirements for components made of various plastics, sheet metal and aluminium. In particular for e-mobility such as fire protection for battery systems.

Fire protection in electrical engineering / information technology

With the HENSOTHERM® | HENSOMASTIK® products, we offer solutions for fire protection requirements for components made of plastics, sheet metal, aluminium, stainless steel, on electrical cables, on pipes and for joint sealing. > Read more

Fire protection in door and window construction

With the HENSOTHERM® | HENSOMASTIK® products, we offer solutions for fire protection requirements for components made of plastics, sheet metal, aluminium, stainless steel and for joint sealing in door and window construction. > Read more

Fire protection for substrates

With the HENSOTHERM® | HENSOMASTIK® products, we offer solutions for fire protection requirements on various substrates made of sheet metal, stainless steel, aluminium, plastics, wood, insulation, Styropor, Styrodur, electrical cables and pipes.

Our core competence – your competitive edge

We offer the development, testing and production of intumescent and ablative building materials, components and coatings as a service – also as a partner for research projects, e.g. under the German Act on Tax Incentives for Research and Development or other EU programmes.

Intumescent materials such as expandable graphite, expand under the influence of heat and increase greatly in volume, so that a protective insulating layer is formed which delays the passage of heat and can also seal cavities. However, a strong expansion is not synonymous with better fire protection performance! The temperature that triggers intumescence and the reaction time until the maximum height of the intumescent layer is reached, as well as the stability and the inflation pressure of the intumescent layer formation, must be optimally adjusted to the respective application. For example, for intumescent strips made of HENSOTHERM® 7 KS fabric with self-adhesive lamination, which are used for fire protection upgrading of doors, windows, battery packs or electrical cabinets.

Ablative substances, on the other hand, delay the heat transfer to the materials to be protected by releasing chemically bound water. In addition to this “cooling effect”, the fire gases are diluted, i.e. the toxicity of the gases is reduced. For example, escape and rescue routes thus remain passable for longer, and there is less smoke-related obstruction of visibility. In addition, our ablative waterproof, oil- and gasoline-resistant fire protection coating HENSOMASTIK® 5 KS paint not only has an EPD, it is also weatherproof, UV-resistant, ageing-resistant and mechanically resilient.

These properties can also add value to your product. Just turn our know-how into your competitive edge!

Advantages of a competent development partner

- Many years of experience in the development of new fire protection products

- Qualified team of development engineers

- Close cooperation and fast response times

- Environmentally friendly and sustainable products have long been a focus at Hensel and have been in the portfolio for years

- International cooperation for worldwide industry standards

- Broad international network of industry experts and decision makers

- Your choice – Complete systems or individual requirements for the safety product, components, corrosion protection or top coats etc.

- Short distances – fire resistance tests carried out in three in-house calibrated fire furnaces and extensive testing facilities in our own test laboratory

- Expertise in applying for and obtaining building code usability certificates

- Support from recognized industry experts

- High-quality products – production facility in Germany with high-quality production machinery, excellently trained employees and multi-stage quality control

- Complete documentation of manufacturing processes – ISO 9001 certified since 1997

- Continuous market-oriented development for a wide range of applications

- Practical and cost-efficient solutions

Research seal: INNOVATIVE THROUGH RESEARCH

Since 2014, the Stifterverband has been honoring research-based companies for their special responsibility, which they take over for state and society, with the seal “Innovative through research”.

BSFZ Seal – Innovation Competence through Research & Development

A seal for (partially) in-house R&D projects as proof of in-house R&D performance.

https://www.bescheinigung-forschungszulage.de/infothek/bsfz-siegel