Fire-protection coating systems for wood

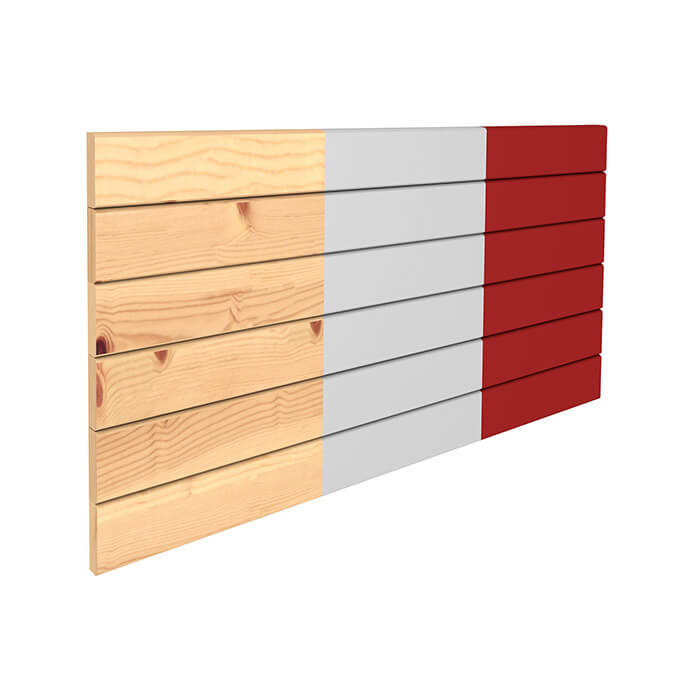

HENSOTHERM® fire-protection coating systems for wood exhibit not only outstanding fire-protection properties, but also long service lives. These coatings are available for both indoor and outdoor applications, and can take protective topcoats in virtually all RAL colours for custom colour schemes or transparent solutions presenting the natural wood grain and texture.

Fire-protection paint for upgrading the building material class of timber

In Germany, the building regulations applying in each state define the minimum combustibility and fire resistance time requirements for the materials employed in building. Unlike masonry, concrete, and steel, untreated timber is combustible and classified B2 (normally combustible) as a building material. This imposes limits on the use of structural timber in multistorey buildings.

The fire protection systems applied to timber structures in Germany are subject to special rules listed in § 51 of its model building ordinance MBO. These have been regulated since June 2021 by the guideline on fire protection requirements for components and external wall cladding in timber construction MHolzBauRL issued by the German technical authority in the construction sector DIBt, a guideline that superseded the sample guideline on fire protection requirements for highly fire-retardant components in timber construction M-HFHHolzR of 2004.

This imposes stricter fire-protection rules specifically for tall structures of timber.

Many of the untreated natural and engineered woods used in timber structures are classified B2 as defined under DIN 4102-1 or EU D-s2,d0 under DIN EN 13501-1 (SBI test), and are therefore deemed “normally combustible” building materials.

Depending on the fire-protection system, its application may upgrade this class to B1 (flame retardant), under DIN 4102-1, or B-s1,d0, under DIN EN 13501-1 (SBI test). In other words, timber may be used where flame-retardant building materials are stipulated – without sacrifice to the advantages of timber as an architectural element.

Accordingly, a fire-protection coating on wood does not affect its fire resistance time, only its building material class.

Benefits of HENSOTHERM® fire-protection systems for wood

Hensel is and remains the leading innovator. With its HENSOTHERM® 2 KS AUSSEN, Rudolf Hensel GmbH was the world’s first manufacturer to develop coatings also for outdoor applications exposed to weather conditions.

Our HENSOTHERM® fire-protection coating systems for wood can take protective topcoats in virtually all RAL colours for custom colour schemes tailored to your project.

Our development work focuses on the environmental compatibility and sustainability of our HENSOTHERM® and HENSOMASTIK® fire-protection coating systems for use in passive constructional fire protection. Also fire-protection systems for wood have been developed, in the form of products in our “Green Product” line, predominantly those fire-protection products which do not contain volatile organic compounds (non-VOC) and thus qualify as building materials for ecological construction.

Our fire-protection coatings have been classified as building materials for ecological construction as defined by the criteria of the US LEED seal of quality. LEED stands for Leadership in Energy and Environmental Design. This quality seal imposes strict standards on candidate building products. The products now certified also include the transparent fire-protection system for wood HENSOTHERM® 1 KS INNEN. The VOC content of HENSOTHERM® 1 KS INNEN is less than one percent, and the associated protective paint HENSOTOP 84 AF contains no aromatic hydrocarbons.

HENSOTHERM® 2 KS INNEN weiss was classified under VOC emissions A+. The recommended classification is based on the French regulation for labelling building products or wall panelling, flooring, paints, and lacquers with respect to their emissions of volatile contaminants, as published on 25 March 2011 (décret DEVL1101903D) and 13 April 2011 (arrêté DEVL1104875A).

Hensel is made in Germany. HENSOTHERM® and HENSOMASTIK® are developed and produced exclusively at our company base in Börnsen near Hamburg. The high quality standards applying to our fire-protection coating systems are safeguarded by our own laboratory and test facilities, long-term weather exposure tests, and continuous analyses of the input stock and production stages.

Timber constructions for sustainability, climate protection, and ecology

The ubiquitous demands for greater sustainability in the construction sector have led to the intensified use of timber in the planning of new office, administrative, and residential buildings.

Building with renewable resources on the cradle-to-cradle principle requires construction materials that are produced with the minimum environmental impact and can be reintroduced to other purposes at the end of their lifecycle. Building materials of renewable resources retain longer the original carbon dioxide that the vegetation had absorbed during its growth, and as a rule require only little energy for their production. In other words, timber construction can save over 50%of the CO2 emissions generated by concrete and steel.

Timber is ecological, their structures are long lived, and their high “prefabricated” levels ensure short construction times. Timber is also the preferred choice where indoor rooms are to impart a healthy, pleasant, feel-good ambience. In addition, natural and engineered woods exhibit excellent insulating properties.

Rudolf Hensel GmbH has been a member of the Institut Bauen und Umwelt e.V. (IBU) since 2014.

IBU is an initiative set up by building product and building component manufacturers who have decided to join forces to meet the demand for greater sustainability in the construction industry. Together we develop sustainable fire-protection systems for a safeguarded, clean future. In the DGNB Navigator, a comprehensive online database, several of Hensel’s “Green Product” fire-protection products have been registered since 2014 under the heading ‘Brandschutzbeschichtungen (fire-protection coatings)’. This is where architects, planners, developers, and everyone involved in building projects can find detailed information on the products and their environmental impact parameters, for calculating lifecycle costs, energy consumption, or emission behaviour.

Applications of HENSOTHERM® fire-protection systems for wood

Intumescent coatings are applied as opaque or transparent coverings on wooden components. When exposed to fire, these coatings swell to a high volume that protects the underlying timber and either prevents or retards its ignition. Fire-protection coatings for wooden components can be applied to small surfaces with rollers or brushes. Larger areas can be treated with airless sprayers supplied with electric or pneumatic piston pumps.

Before all work, specifically the substrate must be tested for its compatibility! The surfaces to be coated must be free of dust, dirt, grease, wax, parting layers, old paint, glues, lime, oil, etc. If necessary, the substrate must be roughened and treated with a deep primer. All vestiges of old coatings must be removed, and highly absorbent substrates should then be treated with a preliminary coating of suitable deep primer that prevents the fire-protection coating penetrating the wooden components too deeply. Parting agents on inadequately roughened substrates may promote the formation of so called fish eyes, or circular spots of fire-protection coating separating from the substrate.

On all woods, a suitable representative area must first be tested prior to the coating measures.

Who may prepare and apply HENSOTHERM® fire-protection systems for wood?

The technical and legal requirements for the professional planning, execution, and documentation of fire sealing are high and intended to provide the best possible protection for life and property in the event of a fire.

Yet also private end customers may apply fire-protection coatings to wooden structures themselves. However, these coatings affect safety, so the ambient, processing, and coating thickness requirements must be observed meticulously.

HENSOTHERM® fire-protection systems and coatings for wood should therefore be prepared and applied by specialists or other individuals who have gained adequate experience in this field.

How do fire-protection systems for wood work?

On exposure to fire, the fire-protection systems for wood swell to present a high-volume, heat-repellent layer that protects the underlying wood, either prevents or retards its ignition, and serves to throttle the mass burning rate. The structural integrity of wooden components treated with this fire-protection system is therefore maintained longer.