Fire protection systems for penetration seals

Below you will find an overview of our DIN and EN approved HENSOTHERM® and HENSOMASTIK® fire protection systems for the construction of fire protection sealings for single penetration and mixed penetration seals. With a simple mouse-click you will be forwarded to the corresponding fire protection system and the corresponding downloads.

Do you have questions about our products or need expert advice for your project? Then give us a call on +49 40 72 10 62-48 or send us an e-mail.

Filter product systems by

Technical assessment

Type

Penetrating services

Long-term success and flexibility in application thanks to extensive fire tests

The HENSOMASTIK® and HENSOTHERM® product systems for fire penetration seals not only stand for excellent product quality, easy workability of all components and practical designs. The high flexibility in the application of our products with a wide range of commercially available pipes and insulation materials and brands also ensures the long-term success of our business partners.

The EN 1366-3 test standard for firestop penetration seals stipulates that, especially in the case of brand-name pipes and insulation made of flexible elastomeric foam or synthetic rubber that are not manufactured in accordance with a specific standard, the test or successful classification will apply only to the exact type, pipe diameter, wall thickness and insulation thickness tested.

Since all manufacturers are constantly developing their products further and new high-performance plastics and composite materials for e.g. highly sound-insulated or even more energy-saving installations are constantly coming onto the market, the manufacturers of fire protection penetration seals are also constantly required to test and classify these in combination with their product systems in new fire tests. Therefore, the tests and classifications of product systems for fire penetration seals, which have to be performed and extended regularly, are very cost-intensive and time-consuming.

Long processing times of the Technical Assessment Bodies (TAB) between fire test and issuance of a new ETA and especially an aBG can quickly lead to the fact that a fire penetration seal system can no longer or not yet be used for the latest generation of pipes and insulation materials. The same applies to the use in modern and increasingly demanded construction elements made of solid wood or cross-laminated timber (CLT).

Hensel, as an innovation leader in the field of passive fire protection, therefore regularly tests pipes and insulation from various manufacturers in different wall and ceiling constructions in conjunction with different product systems in up to 20 external tests per year – for fire penetration seals alone, i.e. not counting the numerous tests of fire protection coatings for steel, concrete or wood structures. In addition, there are numerous smaller fire tests in the company’s own fire furnaces in order to investigate new materials, assembly variants or construction elements in smaller initial test series.

Through participation in standardization committees, Hensel is also always up to date with the latest developments, especially with regard to the current changes in building law, the rules on building products and the fire behaviour of new construction types.

Hence, always remain flexible in your application and be successful in the long term – Rely on tested quality from Hensel!

Soft or hard fire penetration seal? Pipe collar, filler compound or wrap? Which product system is the best fit?

Inside buildings, especially in modern residential and office buildings, a large number of cables and pipes run. They are routed through walls and ceilings by creating special openings for them. However, in the event of a fire, smoke and fire can also make their way through these openings.

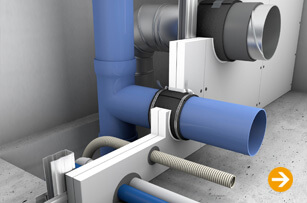

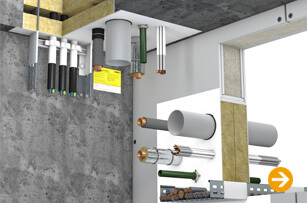

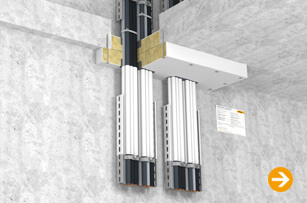

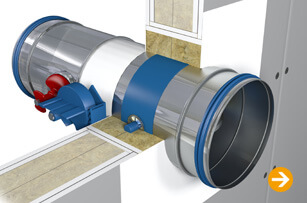

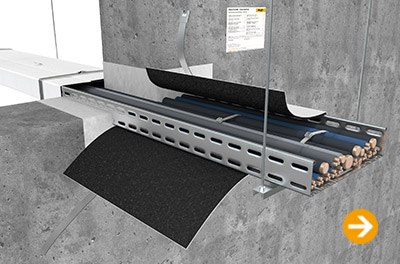

Fire penetration seals, also referred to as firestop or fire protection seals, are used to restore the fire resistance of a construction element after the installation of supply lines such as electrical and piping systems, cable trays, ventilation and air conditioning ducts, and support systems led through openings in walls and floors. In the event of a fire, fire penetration seals ensure that smoke, fire and heat are not transferred from one room or storey to another, or are prevented from spreading long enough to allow evacuation of the building and effective firefighting by the fire department.

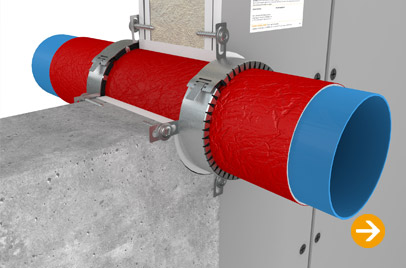

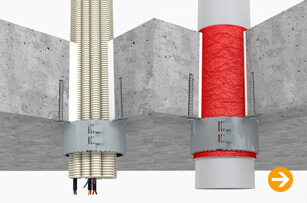

A fire penetration seal system must be made of non-combustible building materials and essentially forms an insulation against the heat and oxygen supply by means of an intumescent fire protection compound, e.g. expandable graphite that will start to foam and expand greatly at high temperature and fill voids or openings left by burning pipes or insulation.

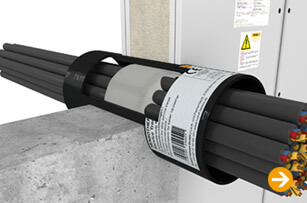

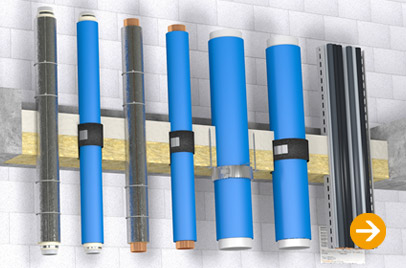

Soft fire penetration seal systems, such as our HENSOMASTIK® EI90/EI120 or EI60 firestop seals for mixed and multiple penetrations, are the most commonly used form. A soft firestop seal consists of high-density mineral fibre boards, which are fitted into the aperture in one single or two layers and worked around the pipes. The mineral fibre boards are treated with additional coatings and the annular gaps sealed with different filler compounds. A mixed fire penetration seal system allows that a combination of different conduits, e.g. cables and pipes, can be lead through and sealed in the same opening. While a multiple fire penetration seal allows to seal multiple conduits of the same type, e.g. a series of five electrical installation conduits in a row. Soft fire penetration seal systems have a sound-absorbing effect, are easy to install and, if necessary, additional conduits can be subsequently added until up to 60% of the seal’s cross section are occupied. Hence, allow for reserve and plan larger openings!

Single penetrations of pipes, cables or electrical installation conduits through core drillings can be sealed, for example, with the systems HENSOTHERM® 7 KS viskos, a fire protection compound filler from the cartridge, or HENSOTHERM® 7 KS Gewebe 50 endless pipe wraps. Also, HENSOTHERM® RM30 / RM50 pipe collars may be used.

To form a firestop seal in larger openings, also with irregular shapes, HENSOTHERM® M 2000 fire protection mortar is best suitable. HENSOTHERM® M 2000 is fiber-free, and allows for multiple and mixed penetrations at most competitive cost.

For areas with limited or single-sided access, or occupation > 60 % of the opening’s cross section, which often is the result of excessive retrofitting of electrical wiring, a pattressed one-sided soft fire penetration seal, such as the HENSOMASTIK® 5 KS Vorschott, can help. The surface-mounted HENSOMASTIK® 5 KS Vorschott may also be used to seal openings with irregular shapes.

All fire penetration seal solutions are standardized in the European economic area and the applications summarized in a European Technical Assessment (ETA). This technical assessment is additionally flanked in Germany by the general building approval (abZ) and the general type approval (aBG) or, for example, in Switzerland by the approval of the Association of Cantonal Fire Insurers (VKF).

Unfortunately, fire protection materials and product systems, especially in the area of firestop seals, are not approved as a one-fits-all-solution. In fact, they are tested and approved for very narrow applications, i.e. specific combinations of construction elements, opening sizes, penetrating conduits types, pipe diameters and wall thicknesses, insulation materials, and the required fire resistance period and classification. For planners the search for a suitable fire penetration seal solution is both time-consuming and difficult – or was, until now.

Therefore, we at Hensel have digitized all technical assessments for our product systems for penetration seals for our business partners.

The Rudolf Hensel Product Selector for fire protection seals is a free tool for architects, MEP-planners, fire protection, general contractors or installation companies in the field of structural fire protection. It allows to search all technical assessment documents of Hensel (ETA or aBG) for a specific application in only five steps, and be referred to the relevant chapters of the technical assessment document.

Important provisions for the planning, dimensioning and execution of the fire protection seal are available at a glance. Links to the complete documentation of the product systems, including the technical manuals, declarations of performance and installation instructions, are available in the last step. Various options for data export and printing functions ease the collaboration with other project participants.

Registered users may further manage their configured firestop solutions in a password-protected user area, where each fire protection seal is saved with a unique ID and additional project information or user comments. The structured project management supports the planning of the material required for installation of all firestop seals in larger projects, facilitates the project documentation through personal notes and contact information of the project partners.

In addition, registered users may create Building Information Modeling (BIM) content for configured firestop seal solutions from their project area.

Check for yourself and visit www.productselector.de.

Who is allowed to install fire penetration seals?

As fire penetration seals are intended to provide the best possible protection for life and property in the event of fire, the technical and legal requirements for the professional planning, execution and documentation of correct fire penetration seals are high.

For this reason, our HENSOMASTIK® and HENSOTHERM® firestop seal systems, which are rated according to DIN 4102 and DIN EN 1366, may only be planned and installed by specialized companies and expert personnel regularly trained and certified by Hensel.

These companies must prove their qualification to the building owner and confirm the conformity of each penetration seal with its European Technical Assessment (ETA) document and/or the provisions of the General Construction Type Approval (allgemeine Bauartgenehmigung, aBG) as well as the assembly instructions of the product system as part of the documentation in accordance with §85a, Para. 2 of the Model Building Code (MBO) or the respective valid State Building Code (LBO).

The installation of fire penetration seals by private end-users is not possible.