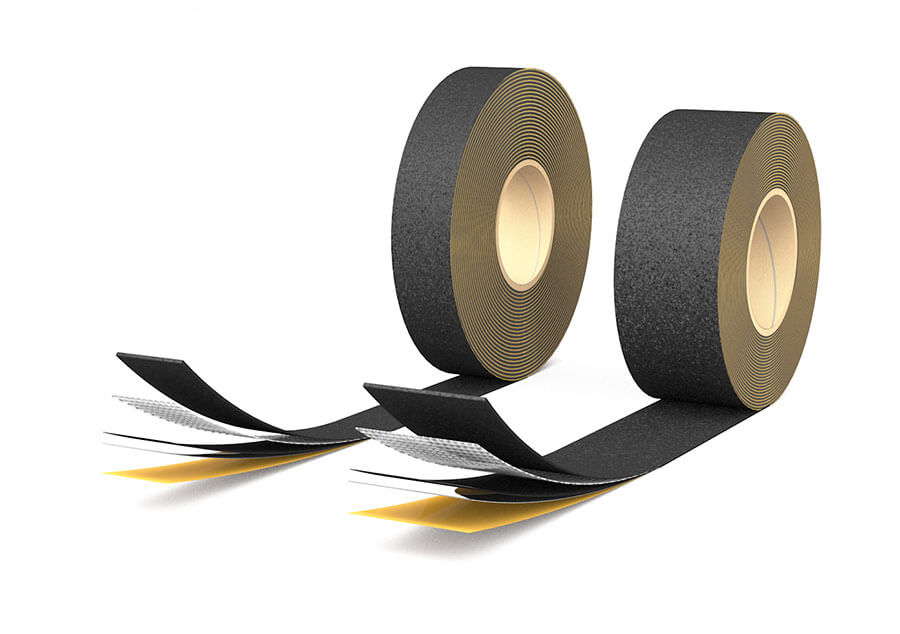

HENSOTHERM® 7 KS Gewebe, HENSOTHERM® 7 KS Gewebe SKL

Intumescent fabric strips with expandable graphite for industrial applications

HENSOTHERM® 7 KS Gewebe and HENSOTHERM® 7 KS Gewebe SKL (self-adhesive on one side) intumescent fabric strips are available in different widths and thicknesses making them suitable for a wide range of industrial fire protection applications to greatly enhance the fire protection properties of products, machinery and equipment.

The highly flexible fabric strips consist of A2 glass filament fabric coated on one or both sides with the intumescent HENSOTHERM® 7 KS fire protection coating. The HENSOTHERM® 7 KS Gewebe SKL fabric strip is available ex works as a self-adhesive version, which enables quick installation. Both versions can be easily cut to size with a knife or scissors. Also, special and irregular shapes may be punched out.

Intumescent substances such as expandable graphite, also called “foaming”, expand under the influence of heat and increase greatly in volume, so that a protective insulation or intumescent layer is formed, which delays the passage of heat and can also seal cavities.

The HENSOTHERM® 7 KS fire protection laminate reacts and expands strongly under the effect of temperature already from approx. 150 °C, whereby an insulating compact carbon layer is formed with high pressure in the event of fire and protects important components. Due to the low reaction temperature in combination with a high foaming factor and inflation pressure, joints or openings are quickly sealed in case of fire, so that a safe fire and smoke gas sealing of individual components and the entire construction is ensured and toxic fire gases are encapsulated.

The HENSOTHERM® 7 KS fire protection compound coated on the strips is classified according to DIN EN 13501-1 as well as DIN 4102-1 and has high anti-drumming and sound-insulating properties. Even strips of higher nominal thickness remain flexible, do not break and can be processed in tight turns, making them ideal for use in door and window construction, the automotive industry or electrical/information technology.

A high blowing pressure or a strong expansion do not always equate to better fire protection performance. The temperature that triggers intumescence, the reaction time until the maximum height of the intumescent layer is reached, but also the stability and the inflation pressure of the intumescent layer formation can be optimally adjusted to the respective application. Contact us, we will be happy to advise you!

Possible areas of application

- Fire doors made of wood, steel or aluminium

- Facades

- Construction joints in wall and ceiling

- Glazing

- Fire dampers

- Lock case insulation and hinges in doors

- Fire protection panels

- Access panels, partition wall and ceiling constructions

- Switch boxes, safes, cable boxes

- Battery and control cabinets

| Building material approval: | European Technical Assessment, ETA 16/0369 according to EAD 350005-00-1104 | ||||||||||||||||

| Delivery forms: |

HENSOTHERM® 7 KS Gewebe fabric strips

HENSOTHERM® 7 KS Gewebe SKL fabric strips (self-adhesive on one side)

Special formats are available on request. |

||||||||||||||||

| Tolerance: | Nominal width ± 0,5 mm Nominal thickness ± 0,2 mm |

||||||||||||||||

| Colour: | Anthracite grey | ||||||||||||||||

| Density: | 1200 kg/m3 ± 60 kg/m3 (bulk density HENSOTHERM® 7 KS) | ||||||||||||||||

| Reaction to fire: | Building material class C-s2,d0 according to DIN EN 13501-1 with nominal thickness 1 mm, corresponds to B1 flame retardant according to DIN 4102-1, other building material class E according to DIN EN 13501-1, corresponds to B2 normal flame retardant according to DIN 4102-1 |

||||||||||||||||

| Start of reaction: | The chemical reaction (expansion/foaming) starts at about 150 °C | ||||||||||||||||

| Foam factor: | 8- to 23.5-fold (loaded according to EAD 350005-00-1104) 30- to 60-fold (without surcharge) |

||||||||||||||||

| Inflation pressure: | Nominal thickness 1 mm: 0,90 N/mm2 to 2,20 N/mm2 Nominal thickness 2 mm: 0,45 N/mm2 to 2,50 N/mm2 |

||||||||||||||||

| Direction of action: | Three-dimensional, voluminous mass as emerging inflated body | ||||||||||||||||

| Processing: | +10 °C bis +25 °C bei ≤ 80 % relative humidity | ||||||||||||||||

| Surface preparation: | Ensure that the surface is free of dust, grease and oil, carry out adhesion tests if necessary! | ||||||||||||||||

| Storage: | Store in a cool and dry place at +5 °C to +25 °C. Protect from frost and heat! |

||||||||||||||||

| Use category: | Type X (includes classes Y1, Y2, Z1, Z2), weather-resistant, resistant to moisture, frost and UV radiation, suitable for use in interior and protected exterior areas without driving rain. Additional verifications for

|

||||||||||||||||

| Paintability: | Can be painted over with all commercially available paints and on the basis of acrylic dispersion, alkyd resin, polyurethane acrylic and epoxy resin. | ||||||||||||||||

| Environment: | Green Product, classified in VOC emission class A Contains no hazardous substances according to Regulation (EC) No. 1272/2008 Non-hazardous material according to GefStoffV, free of asbestos, lead, mercury and chrome Solvent-, halogen- and plasticiser-free |

-

Contact

Technical support / Sales

Tel: +49 40 721062-48

Fax: +49 40 721062-52

Send email